DEFINITION

What is a digital twin?

A digital twin is a virtual replica of a physical object or process that can update itself in real-time. Most examples use sensors and various systems integrations to monitor their real-world counterparts and control their functions remotely.

While this technology is relatively new, the digital twin market is rapidly expanding. One Gartner digital twin study found that 62% of organizations with Internet of Things (IoT) functionality are establishing these systems or intend to do so. Meanwhile, 13% of respondents already have digital twins in place at their installations.

ADVANTAGES

What are the benefits of digital twins?

Virtual troubleshooting

Digital twins make it possible to track and troubleshoot equipment and inventory remotely. These capabilities enhance technician productivity and contribute to the operational effectiveness of on-site assets.

Predictive maintenance

Digital twins leverage machine learning techniques to estimate when equipment is at risk of breaking down, automatically flagging assets for review and preventative repair.

Indoor mapping

Using integrated building sensors, digital twins can render physical spaces as 3D layouts. These representations can be used for navigation, testing furniture layouts, and analyzing real-world event data.

Reduced costs

Digital twins save money by streamlining organizational efficiencies, maximizing equipment lifespans, and optimizing workspaces for employee health and performance.

DIGITAL TWIN EXAMPLES

What challenges do digital twins solve?

The first digital twins were part of NASA research for managing spacecraft simulations. Today, they are excellent tools for automating repetitive tasks, reducing costs, and increasing productivity in any workplace. Businesses across all industries rely on digital twins to enhance their day-to-day operations. Here are a few examples:

Healthcare

Digital twin technology makes it possible to provide more personalized medicine, accelerate clinical trials, and even model genomes. By creating a virtual twin of an individual, doctors can test prescriptions for safety and efficacy in advance of treatment.

Construction

Digital twins can act as architectural visualizations of any 3D space. Such tools can accelerate design and production processes while providing a richer understanding of costs and construction times.

Oil & Gas

Digital twins predict maintenance issues in oil fields and refineries thanks to IoT sensors. These capabilities are instrumental when simulating activity deep underground that cannot be accessed quickly or readily.

Automotive

Digital twins are common in modern automotive design and production. Connecting virtual models to individual vehicles lets manufacturers test and analyze cars in driving conditions before they reach the road.

Manufacturing

Digital twins let manufacturers

virtually replicate their entire production chain to identify and resolve pain points.

This capability helps industries predict

raw material shortages and reduce

on-site downtime.

Facilities Management

Digital twins make it easier to manage and automate facility operations. By installing IoT sensors, managers can track asset locations and log real-time events remotely. Meanwhile, the system automatically flags assets for preventative repair, increasing overall efficiency and cost-effectiveness.

Retail

Digital twins can represent retail storefronts right to the product level, allowing for precise sales analysis. Category managers can simulate store layout and product placement changes while leveraging data on traffic flows, hot spots, and real-time user behavior.

Real Estate

Digital twins quickly highlight features

of physical real estate of interest to prospective tenants and investors. While on-site, these replicas can also optimize building operations like HVAC systems based on occupancy patterns.

Supply Chain Management

Digital twins are increasingly vital to managing supply chain logistics networks. Once implemented, they can optimize distribution routes by traffic, maximize inventory efficiency, and even test product packaging effectiveness.

DIGITAL TWIN COMPARISON

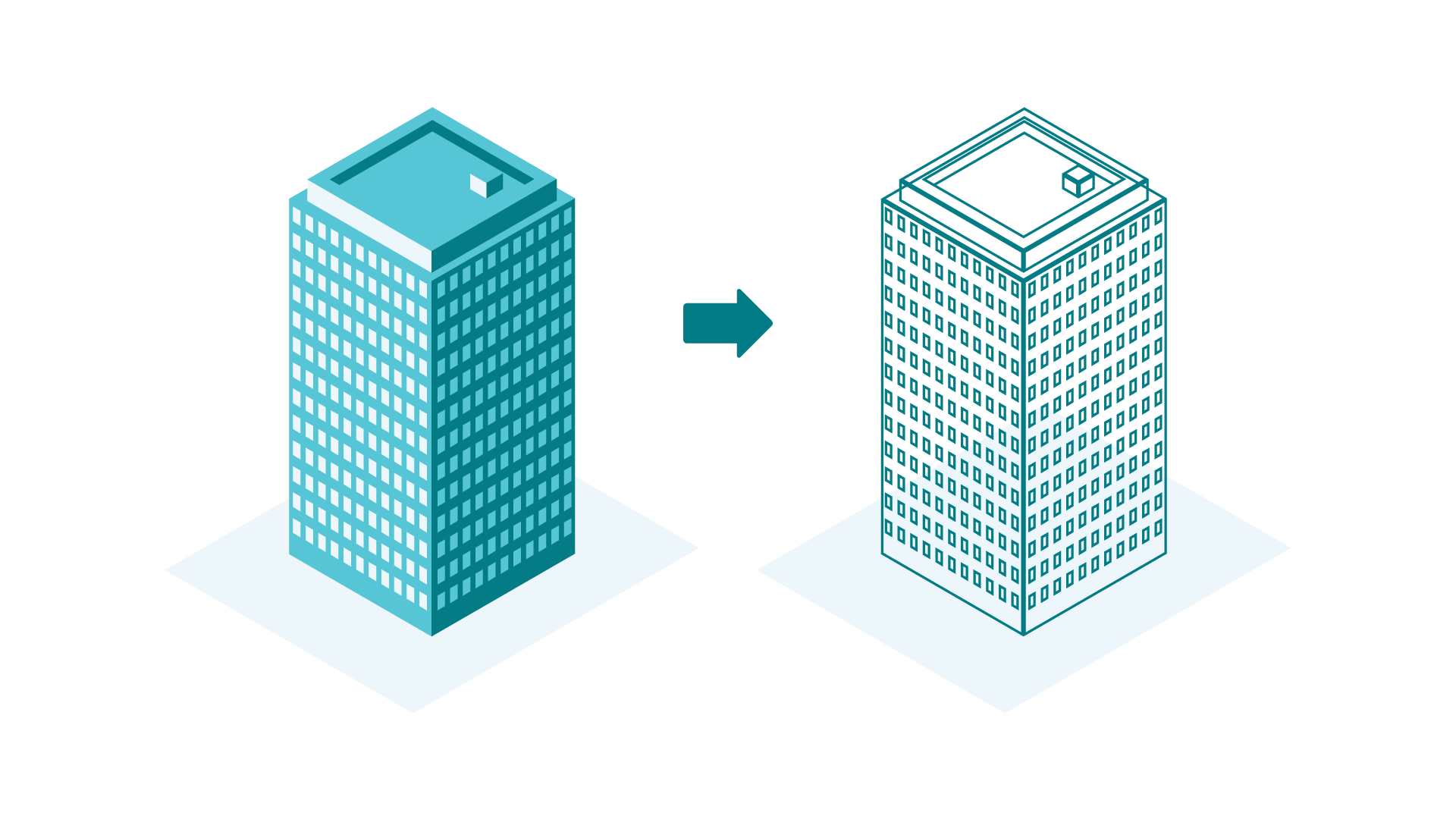

What is the difference between BIM and digital twins?

Building information modeling (BIM) and digital twin technology are invaluable parts of building design and management, but they are unique solutions to specific problems.

Where BIM is the process of creating 2D or 3D digital representations of physical spaces to assist architects, digital twins connect to existing locations in real-time.

These tools can work in tandem to assist architects with renovations and fully tap into physical spaces’ potential.

DIGITAL TWIN VS SIMULATION

What is the difference between digital twins and simulations?

A traditional computer simulation is helpful when calculating what might happen.

Digital twins go a step further by analyzing future events and what is currently happening in real-time. This capability enhances the value of digital twins as a predictive tool and a property management platform.

DIGITAL TWINS IN ACTION

How to create a digital twin

There are three primary considerations needed when designing any digital twin:

Information

What kind of information will you transmit through the system? Binary data, such as whether a lighting system is on or off, will be reasonably simple. On the other hand, ongoing data such as location trackers or motion sensors will be far more complex.

Equipment

What kind of equipment will integrate a physical space with the digital twin? Most examples use some type of sensor representing activity within a given area, but not all sensors are equal. A location tracker in a medical facility will operate differently than a seismic monitor at a natural gas refinery. What’s more, you’ll need to ensure infrastructure is available to transmit data through local cables or wireless signals.

Features

What features are necessary for the digital twin control system? If you intend to manage the physical space remotely, it will need to transmit data back to the physical location. There’s also the question of whether operators will work from a computer, smartphone app, or other digital devices.

No two digital twins are alike, but these steps will help you create a design that matches your location’s specialized needs.

DIGITAL TWIN SOFTWARE PLATFORMS

Meet Vera

Vera transforms buildings into intelligent digital twins with embedded AI and real-time data, creating environments where people and devices operate seamlessly. Vera enables context-aware applications for efficient operations and personalized, engaging experiences in office buildings, retail stores, healthcare facilities, and much more.

Resources

How AR Can Maximize the Value of a Lean Facilities Management Staff

The COVID-19 outbreak has put a strain on the global economy, and as a result, many businesses are...

3 Ways Retailers Can Use Augmented Reality to Increase Sales

In a world where everything is online and connected, many retailers are using modern technology...

Leading Retail Brands Profiting From Experiential AR

As our real and digital worlds become interconnected, augmented reality (AR) proves itself to be...